Kanema

Kufotokozera mwachidule

TP-TGXG-200 Automatic Bottle Capping Machine imagwiritsidwa ntchito kupukuta zisoti pamabotolo okha. Amagwiritsidwa ntchito kwambiri muzakudya, zamankhwala, m'mafakitale amankhwala ndi zina zotero. Palibe malire pa mawonekedwe, zinthu, kukula kwa mabotolo abwinobwino ndi zisoti zomangira. Mtundu wosalekeza wa capping umapangitsa TP-TGXG-200 kuti igwirizane ndi liwiro la mzere wonyamula. Makinawa ali ndi zolinga zingapo, zomwe zimagwiritsidwa ntchito kwambiri komanso zosavuta kugwira ntchito. Poyerekeza ndi mtundu wanthawi yayitali wogwirira ntchito, TP-TGXG-200 ndiyochita bwino kwambiri, kukakamiza kwambiri, komanso kuwononga zipewa.

Kugwiritsa ntchito

Makina a automatic capping amatha kugwiritsidwa ntchito pamabotolo okhala ndi zomata zomata mosiyanasiyana, mawonekedwe komanso zida.

A. Kukula kwa botolo

Ndi oyenera mabotolo ndi 20-120mm awiri ndi 60-180mm kutalika. Koma imatha kusinthidwa pakukula kwa botolo loyenera kupitilira izi.

B. Maonekedwe a botolo

Makina ojambulira okha amatha kugwiritsidwa ntchito pamawonekedwe osiyanasiyana ngati masikweya ozungulira kapena mawonekedwe ovuta.

C. Botolo ndi chipewa

Kaya pulasitiki yamagalasi kapena chitsulo, makina ojambulira okha amatha kuthana ndi zonsezi.

D. Screw cap mtundu

Makina ojambulira okha amatha kuwononga mitundu yonse ya screw cap, monga mpope, kupopera, kapu yoponya ndi zina zotero.

E. Makampani

Makina ojambulira okha amatha kujowina mafakitale amitundu yonse ngakhale ndi ufa, madzi, granule packing line, kapena ndi chakudya, mankhwala, chemistry kapena mafakitale ena aliwonse. Kulikonse komwe kuli zisoti zomangira, pali makina ojambulira okha oti mugwire nawo ntchito.

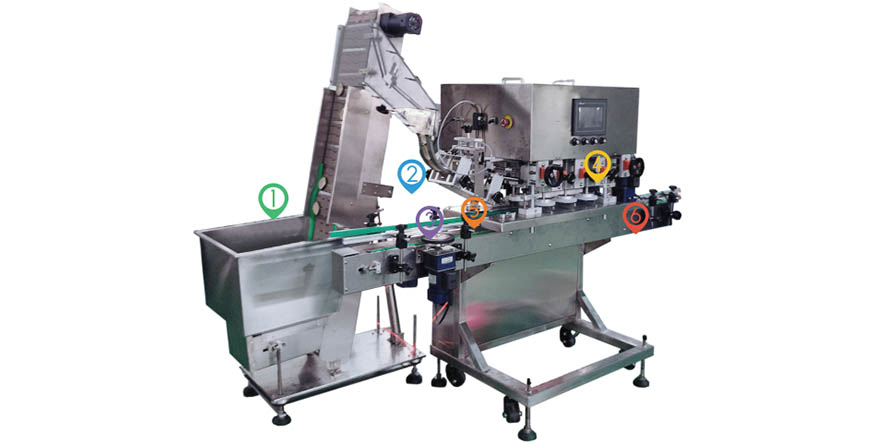

Ntchito yomanga & ntchito

Zimapangidwa ndi makina opangira capping ndi cap feeder.

1. Kapu feeder

2. Kuyika kapu

3. Cholekanitsa mabotolo

4. Mawilo otsekera

5. Botolo clamping lamba

6. Lamba wotumizira botolo

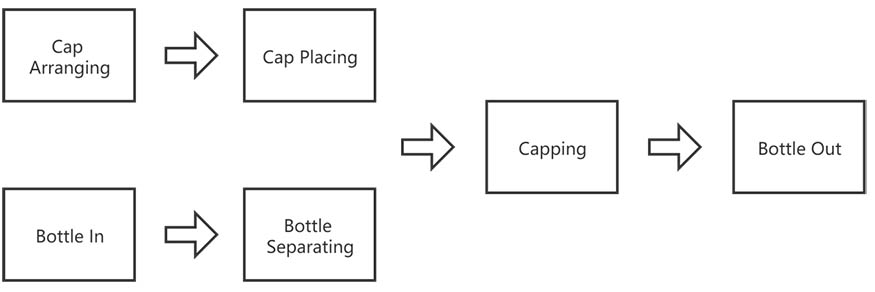

Zotsatirazi zikugwira ntchito

Mawonekedwe

■ Amagwiritsidwa ntchito kwambiri m'mabotolo ndi zipewa zamitundu yosiyanasiyana ndi zinthu.

■ PLC& touch screen control, yosavuta kugwiritsa ntchito.

■ Kugwiritsa ntchito kosavuta komanso kusintha kosavuta, kupulumutsa anthu ambiri komanso mtengo wanthawi.

■ Kuthamanga kwakukulu ndi kosinthika, komwe kuli koyenera kwa mitundu yonse ya mzere wolongedza.

■ Ntchito yokhazikika komanso yolondola kwambiri.

■ Batani limodzi loyambitsa ntchito limabweretsa kumasuka kwambiri.

■ Kupanga mwatsatanetsatane kumapangitsa makinawo kukhala aumunthu komanso anzeru.

■ Chiŵerengero chabwino pamawonekedwe a makina, mapangidwe apamwamba ndi maonekedwe.

■ Thupi la makina limapangidwa ndi SUS 304, kukumana ndi muyezo wa GMP.

■ Zigawo zonse zolumikizirana ndi botolo ndi zotsekera zimapangidwa ndi chitetezo chakuthupi pazakudya.

■ Digital anasonyeza chophimba kusonyeza kukula kwa botolo osiyana, amene adzakhala yabwino kusintha botolo (Njira).

■ Optronic sensor kuchotsa mabotolo omwe ali ndi zolakwika (Njira).

■ Chida chonyamulira chonyamulira kuti chizilowetsa m'zivundikiro zokha.

■ Chivundikiro chomwe chikugwa chimatha kuchotsa zivundikiro za zolakwika (pophulitsa mpweya ndi kuyeza kulemera).

■ Lamba kuti akanikizire zivindikiro amatsatiridwa, kotero izo zikhoza kusintha chivindikiro pamalo oyenera ndiyeno kukanikiza.

Wanzeru

Gwiritsani ntchito mfundo yosiyana pakati pa mbali ziwiri za kapu, kapu yolondola yokhayo imatha kusunthira pamwamba. Chipewa cholowera kolakwika chidzagwa chokha.

Pambuyo pa conveyor kubweretsa zipewa pamwamba, wowuzirayo amawombera zisoti mu kapu.

Cholakwika cha lids sensor chimatha kuzindikira zivindikiro zopindika mosavuta. Zodzikongoletsera zodzitchinjiriza zochotsa ndi sensa ya botolo, fikirani pakuchita bwino

Olekanitsa mabotolo amalekanitsa mabotolo wina ndi mnzake posintha liwiro la mabotolo pamalo ake. Mabotolo ozungulira nthawi zambiri amafunikira cholekanitsa chimodzi, ndipo mabotolo amabwalo amafunikira olekanitsa awiri.

Kapu kusowa kozindikira chipangizo kumawongolera kapu feeder kuthamanga ndikuyimitsa yokha. Pali masensa awiri kumbali ziwiri za kapu, imodzi kuti muwone ngati njanjiyo ili ndi zisoti, ina kuti muwone ngati njanjiyo ilibe kanthu.

Kuchita bwino

Kuthamanga kwakukulu kwa conveyor botolo ndi cap feeder kumatha kufika 100 bpm, zomwe zimabweretsa makinawo kuthamanga kwambiri kuti agwirizane ndi mizere yosiyanasiyana yonyamula.

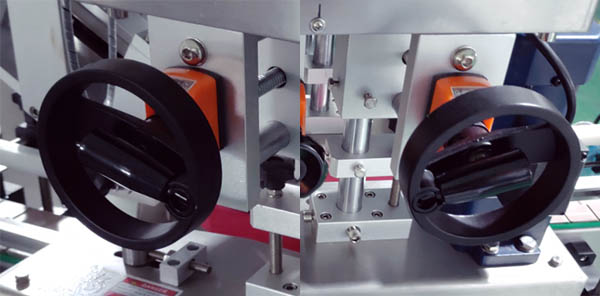

Mawiri awiri a mawilo amapotoza zipewa mwachangu. Aliyense wa awiriwa ali ndi ntchito yeniyeni. Awiri oyamba amatha kutembenukira mobwerera kuti zipewa zovuta zoyika zikhale pamalo ake olondola. Koma amatha kupanga zisoti zokhotakhota kuti zifike pamalo oyenera mwachangu pamodzi ndi mawilo awiri awiriawiri pomwe chipewa chili chachilendo. Awiriawiri achitatu amasintha pang'ono kuti atseke kapu, kotero kuti liwiro lawo ndilocheperapo pakati pa mawilo onse.

Zosavuta

Poyerekeza ndi kusintha kwa gudumu lamanja kuchokera kwa ogulitsa ena, batani limodzi lokweza kapena kutsitsa chida chonse cha capping ndichosavuta kwambiri.

Masinthidwe anayi kuchokera kumanzere kupita kumanja amagwiritsidwa ntchito kusintha liwiro la chotengera botolo, chotchinga cha botolo, kukwera kapu ndi kupatukana kwa botolo. Kuyimbako kumatha kuwongolera woyendetsa kuti afike pa liwiro loyenera pamtundu uliwonse wa phukusi mosavuta.

Mawilo am'manja kuti asinthe mtunda pakati pa lamba wotsekereza mabotolo awiri mosavuta. Pali mawilo awiri kumapeto kwa clamping lamba. Kuyimba kumatsogolera wogwiritsa ntchito kuti afike pamalo oyenera posintha kukula kwa botolo.

Kusintha kusintha mtunda pakati pa ma wheel capping ndi ma caps. Kuyandikira kwa mtunda, kapu idzakhala yolimba. Dial imathandiza wogwiritsa ntchito kupeza mtunda woyenera kwambiri.

Easy ntchito

Kuwongolera kwa PLC&touch screen ndi pulogalamu yosavuta yogwiritsira ntchito, kumapangitsa kuti ntchitoyi ikhale yosavuta komanso yabwino.

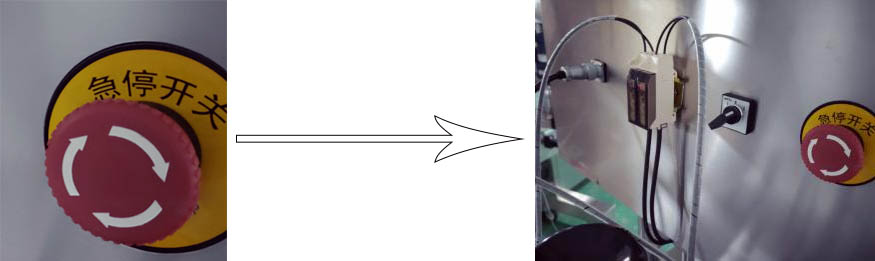

Batani lazadzidzi loyimitsa makina nthawi yomweyo, zomwe zimapangitsa kuti wogwiritsa ntchito azikhala otetezeka.

| TP-TGXG-200 Botolo Capping Machine | |||

| Mphamvu | 50-120 mabotolo / min | Dimension | 2100*900*1800mm |

| Mabotolo awiri | Φ22-120mm (zosinthidwa malinga ndi lamulo) | Kutalika kwa botolo | 60-280mm (zokonda malinga ndi lamulo) |

| Kukula kwa chivindikiro | Φ15-120mm | Kalemeredwe kake konse | 350kg |

| Mtengo woyenerera | ≥99% | Mphamvu | 1300W |

| Zakuthupi | Chitsulo chosapanga dzimbiri 304 | Voteji | 220V/50-60Hz (kapena makonda) |

| Ayi. | Dzina | Chiyambi | Mtundu |

| 1 | Invertor | Taiwan | Delta |

| 2 | Zenera logwira | China | TouchWin |

| 3 | Sensor ya Optronic | Korea | Autonics |

| 4 | CPU | US | ATMEL |

| 5 | Interface Chip | US | MEX |

| 6 | Kukanikiza Lamba | Shanghai |

|

| 7 | Series Motor | Taiwan | TALIKE/GPG |

| 8 | Chithunzi cha SS304 | Shanghai | Zithunzi za BaoSteel |

Makina ojambulira okha amatha kugwira ntchito ndi makina odzaza ndi makina olembera kuti apange mzere wonyamula.

A. Botolo la unscrambler+auger filler+automatic capping machine+makina osindikizira osindikiza.

B. Botolo la unscrambler+auger filler+makina odziyimira pawokha+makina osindikizira osindikiza+makina olembera

ACCESSORIES mu Box

■ Buku la malangizo

■ Chithunzi chamagetsi ndi cholumikizira cholumikizira

■ Buku lothandizira chitetezo

■ Gulu la zida zovala

■ Zida zosamalira

■ Mndandanda wamasinthidwe (chiyambi, chitsanzo, zofotokozera, mtengo)

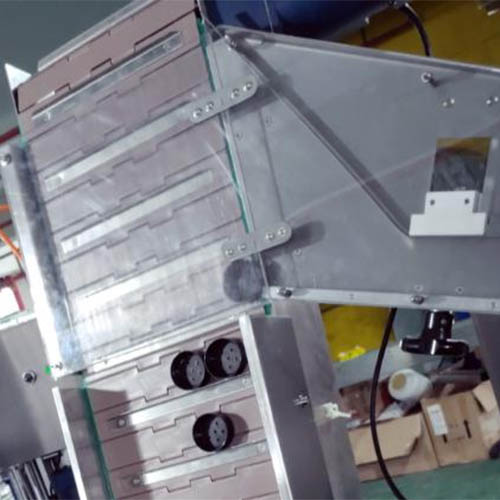

1. Kuyika kapu Elevator ndi kapu kuika dongosolo.

(1) Kuyika kapu yokonzekera ndi sensor yozindikira.

Chokwezera kapu ndi makina oyika amasiyanitsidwa musanatumize, chonde ikani kapu yokonzekera ndikuyika makina pamakina otsekera musanagwiritse ntchito makinawo. Chonde gwirizanitsani dongosololi monga momwe zikuwonekera pazithunzi zotsatirazi:

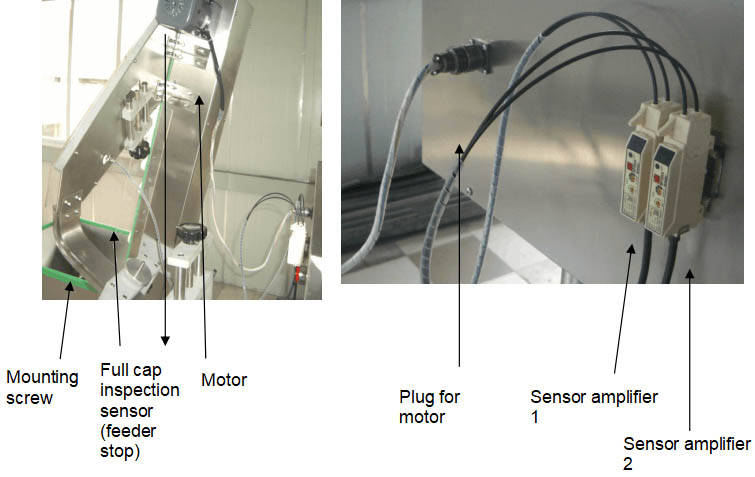

Kusowa kapu yoyendera sensor (kuyimitsa makina)

a. Lumikizani njira yoyikira kapu ndi kanjira ndi zomangira.

b. Lumikizani waya wamoto ndi pulagi kumanja pa control panel.

c. Lumikizani sensor yonse yowunikira ndi sensor amplifier 1.

d. Lumikizani kapu yoyendera sensor ndi sensor amplifier 2.

Sinthani ngodya ya unyolo wokwera kapu: Mbali ya unyolo wokwera kapu yasinthidwa molingana ndi kapu yachitsanzo yomwe mwapereka musanatumize. Ngati kuli kofunikira kusintha mawonekedwe a kapu (ingosinthani kukula, osasintha mtundu wa kapu), chonde sinthani ngodya ya unyolo wokwerera kapu ndi sikona yosinthira makona mpaka unyolowo ungotulutsa zipewa zomwe zimatsamira unyolo ndi mbali yakumtunda. Chizindikiro chotsatira:

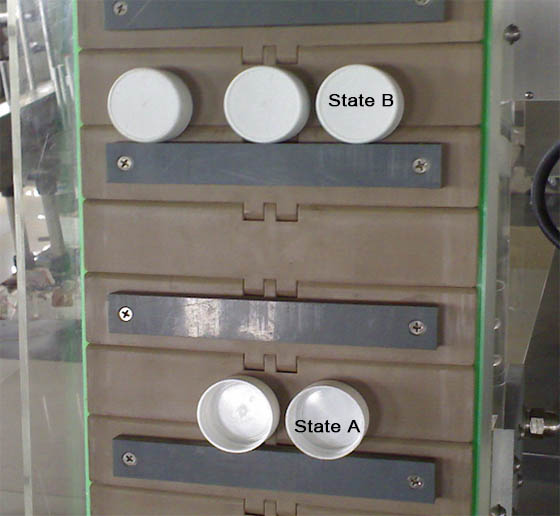

Kapu mu state A ndi njira yolondola pamene kapu kukwera unyolo kubweretsa caps mmwamba.

Kapu mu state B imagwera mu thanki yokha ngati unyolo uli mu ngodya yoyenera.

(2) Sinthani makina ogwetsera kapu (chute)

Ngodya yogwetsa chute ndi danga zakhazikitsidwa kale molingana ndi zitsanzo zomwe zaperekedwa. Nthawi zambiri ngati palibe tsatanetsatane watsopano wa botolo kapena kapu, zokonda siziyenera kusinthidwa. Ndipo ngati pali zochulukira kuposa 1 tsatanetsatane wa botolo kapena kapu, kasitomala ayenera kulemba chinthucho pa mgwirizano kapena chophatikizira chake kuti awonetsetse kuti zasiya malo okwanira kuti zisinthidwe. Njira yosinthira ili motere:

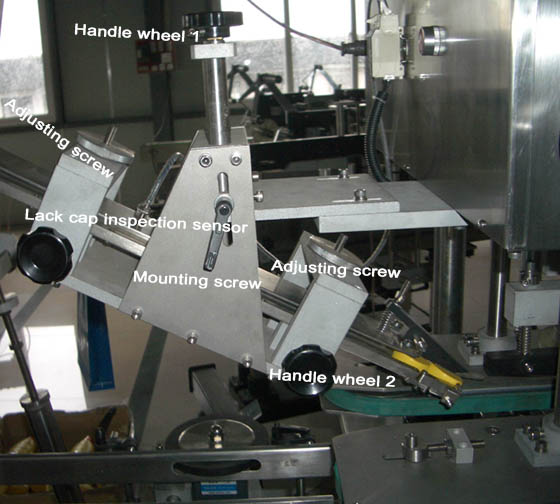

Sinthani kutalika kwa makina ogwetsera kapu: Chonde masulani zomangira musanatembenuzire gudumu 1.

Zomangira zowongolera zimatha kusintha kutalika kwa danga la chute.

Gudumu la chogwirira 2 (mbali ziwiri) limatha kusintha kukula kwa danga la chute.

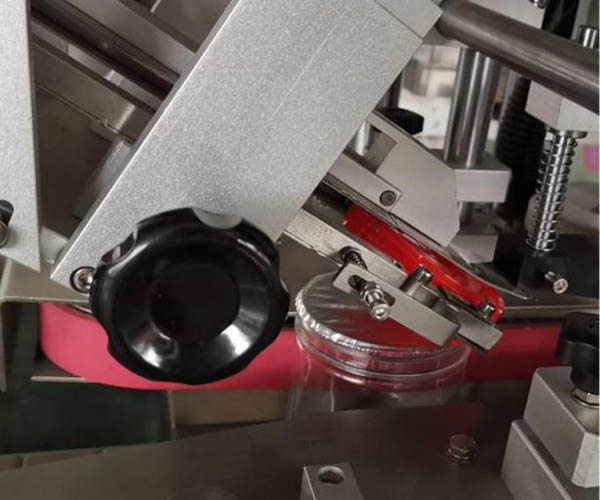

(3) Kusintha kapu yosindikizira gawo

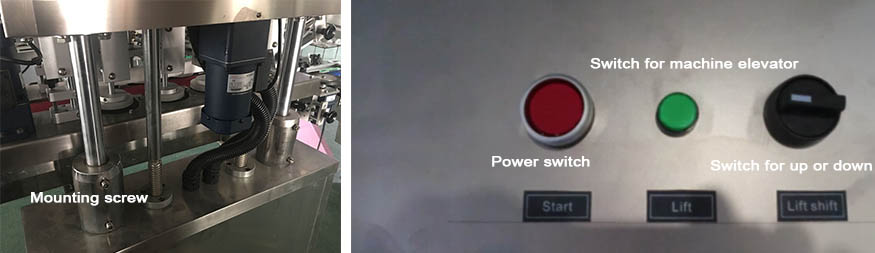

Chophimbacho chimaphimba pakamwa pa botolo kuchokera ku chute pokhapokha botolo likudya mu gawo la kapu yosindikizira. Gawo lokakamiza la kapu limathanso kusinthidwa chifukwa cha kutalika kwa mabotolo ndi zisoti. Zidzakhudza ntchito ya capping ngati kupanikizika pa kapu sikuli koyenera. Ngati malo a cap press part ndi okwera kwambiri, kukakamiza kumakhudzidwa. Ndipo ngati malowo ndi otsika kwambiri, kapu kapena botolo lidzawonongeka. Nthawi zambiri kutalika kwa kapu yosindikizira kwasinthidwa kusanatumizidwe. Ngati wosuta akufunika kusintha kutalika kwake, njira yosinthira ili motere:

Chonde masulani zomangira musanasinthe kutalika kwa kapu yosindikizira.

Palinso kapu ina yosindikizira ndi makina kuti igwirizane ndi botolo laling'ono kwambiri, njira yosinthira ikuwonetsedwa muvidiyoyi.

(4). Kusintha mphamvu ya mpweya kuti muwombere kapu mu chute.

2. Kusintha kutalika kwa zigawo zazikulu zonse.

Kutalika kwa zigawo zazikulu monga kapangidwe ka botolo, chingamu-elastic spin wheel, kapu yosindikizira gawo imatha kusinthidwa lonse ndi elevator yamakina. Batani lowongolera la elevator yamakina lili kumanja kwa gulu lowongolera. Wogwiritsa ntchito ayenera kumasula wononga zomangira pa nsanamira ziwiri zothandizira asanayambe chokwezera makina.

ø amatanthauza pansi ndipo ø amatanthauza mmwamba. Kuonetsetsa kuti malo a mawilo ozungulira akugwirizana ndi zisoti. Chonde zimitsani mphamvu ya elevator ndikumangirira wonongazo mukakonza.

Zindikirani: Chonde kanikizani chosinthira chokweza (chobiriwira) nthawi zonse mpaka mutakhazikika bwino. Liwiro la elevator ndilochepa kwambiri, chonde dikirani moleza mtima.

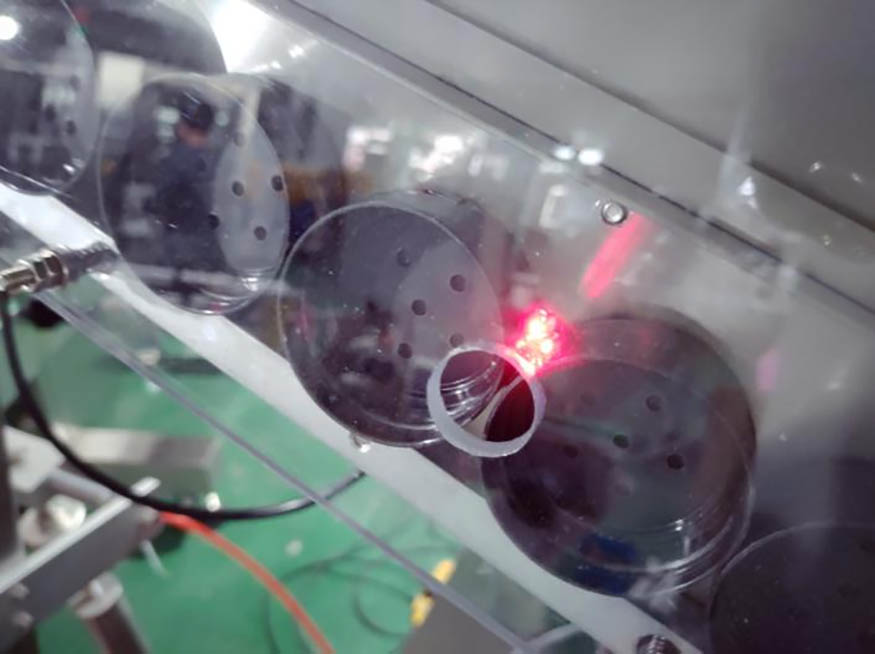

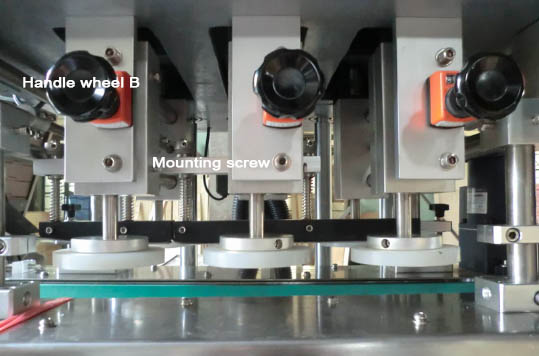

3. Sinthani gudumu la chingamu-elastic spin (mawotchi atatu ozungulira)

Kutalika kwa gudumu lozungulira kumasinthidwa ndi elevator yamakina.

M'lifupi magudumu ozungulira amasinthidwa molingana ndi kukula kwa kapu.

Nthawi zambiri mtunda pakati pa gudumu ndi 2-3mm kuchepera kuposa awiri a kapu. Oyendetsa amatha kusintha kukula kwa gudumu lozungulira ndi gudumu lachitsulo B. (gudumu lililonse lachitsulo limatha kusintha gudumu lozungulira).

Chonde masulani zomangirazo musanasinthe gudumu B.

4. Kusintha kapangidwe ka botolo.

Malo okonzera botolo amatha kusinthidwa mwa kusintha malo akukonzekera ndi kugwirizanitsa axis. Ngati malo okonzerawo ali otsika kwambiri pa botolo, botololo limakhala losavuta kuyika pansi pa kudyetsa kapena kutseka. M'malo mwake ngati malo okonzerawo ali okwera kwambiri pabotolo, amasokoneza kugwira ntchito koyenera kwa magudumu ozungulira. Onetsetsani kuti mzere wapakati wa conveyor ndi mabotolo okonza mabotolo ali pamzere womwewo mutatha kusintha.

Kutembenuza chogwirira A (kutembenuza chogwirira ndi manja awiri pamodzi) kusintha mtunda pakati pa lamba wokonza botolo. Chifukwa chake kapangidwe kake kamatha kukonza botolo bwino panthawi yokakamiza.

Kutalika kwa lamba wokonza botolo nthawi zambiri kumasinthidwa ndi elevator yamakina.

(Chenjezo: Ogwiritsa ntchito amatha kusintha kutalika kwa lamba wokonza botolo mu kachipangizo kakang'ono akamamasula zomangira pa 4 ulalo shaft.)

Ngati wogwiritsa ntchito akufuna kusuntha lamba wambiri, chonde sinthani momwe lamba alili mutamasula wononga 1 ndi screw 2 palimodzi, ndipo ngati wogwiritsa ntchito akufunika kusintha kutalika kwa lamba pang'onopang'ono, chonde masulani wononga 1 yokha, ndipo tembenuzani ndodo yosinthira.

5. Kusintha gudumu la botolo la botolo ndi njanji.

Oyendetsa akuyenera kusintha malo a gudumu losinthira botolo ndi njanji posintha mawonekedwe a botolo. Danga pakati pa gudumu losinthira danga ndi phula liyenera kukhala 2-3mm kuchepera kuposa kukula kwa botolo. Chonde onetsetsani kuti mzere wapakati wa conveyor ndi mabotolo okonza mabotolo ali pamzere womwewo mutasintha.

Tsegulani zomangira zosinthira zimatha kusintha malo a gudumu losinthira botolo.

Wotayirira kusintha chogwirira akhoza kusintha m'lifupi mwa njanji mbali zonse za conveyor.